If there are two values we cling to here at COVAP, they are innovation and tradition. Though these ideas may seem contradictory, they help us maintain culinary flavors derived from hundreds of years of Spanish tradition, while also staying ahead of the trends and continuing to improve even the most timeless products and processes.

We still cure and age all of our jamón, paleta, and cured meats using traditional methods and recipes, and will continue to do so! That means using pure ingredients like sea salt, paprika, garlic, and of course, the best quality pork in the world from the Valle de Los Pedroches in southern Spain. These are the traditions we will forever respect and they will never change.

However, there are so many new ways to ensure we are producing a consistent product all year round. When it comes to maintaining quality and controlling the way each piece is cured, measured, and packaged, we implemented a variety of new and exciting methods. COVAP is utilizing a new technology to measure different properties in the fat of our products, specifically jamón ibérico. This equipment, called NIRS (Near Infrared Spectroscopy), is located on the “backbone” post on a platform, just before the pigs pass through to the hanging room. It measures the subcutaneous fat composition in their carcasses and can quickly predict the distinct saturated and unsaturated fatty acids (palmitic, oleic, linoleic, stearic, to name a few) in a non-invasive manner.

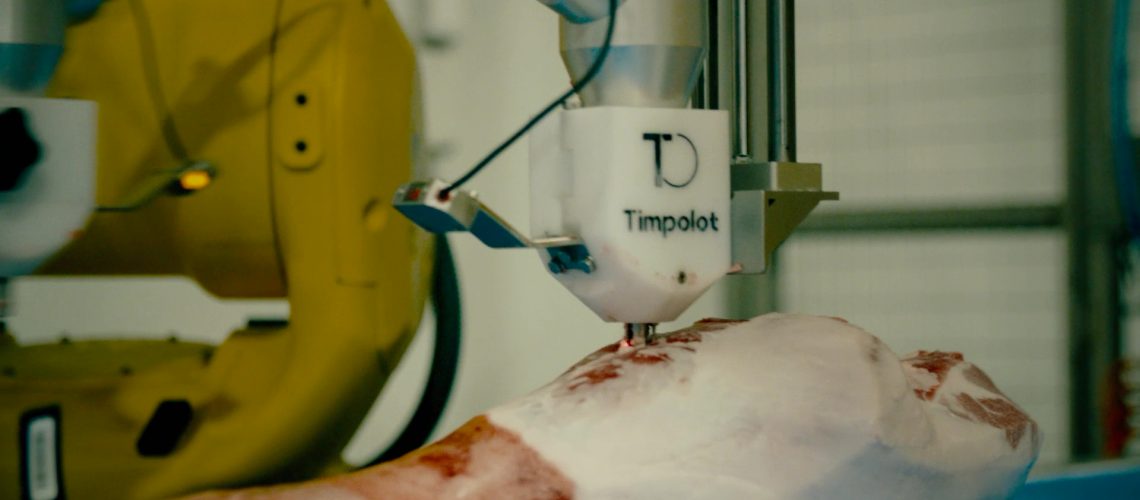

An even more exciting addition to our innovation is the advanced robotics program. We utilize two robot arms to measure the pH levels of our jamón and paletas. The robotic arms have an electrode that is inserted into the leaner areas of the piece (autonomously using AI, regardless of the position of the piece) to determine these levels. These measurements help us take corrective action to ensure even curing throughout, allowing us to correct the salt and adjust levels based on the pH—more salt is added to pieces with higher pH levels.

A few years ago, COVAP also received a Gold Edition cobot from Universal Robots. Unlike conventional robots, these cobots are designed to work side by side with COVAP team members for maximum efficiency, opening up all sorts of avenues for human-robot collaboration in the workplace. COVAP needed to increase production by 50% to keep up with such a growing demand; the cobot’s “pick and place” application helps speed up and improve the vacuum sealing and packaging process so we can produce even more delicious cured meats.

These machines are highly versatile and thus, have a fantastic return on investment, making them a viable option for small producers who often do not have the financial opportunity to scale up. Since COVAP incorporated the cobot into production, we have increased our productivity while still maintaining the absolute highest quality.

At COVAP, we will never stop innovating. Innovation is a key component of improving our business model and ensuring we can continue to deliver the best Spanish products around the world. At the same time, we will always cling to our roots, producing an age-old product with rich history and valuable tradition that you can continue to trust year after year.